Manufacturing

Manufacturing

A Journey Worth Sharing

How one Manufacturing business found a better way to work

- 🛠 Production orders shared verbally or on WhatsApp

- 📦 Raw material received but no record of quantity

- 📉 No idea about current WIP (work in progress)

- 📞 Operator asks for drawing again and again

- 📬 Dispatch delays due to missing packing slips

- 💸 Miscommunication on payment status

- 🧾 Invoices made manually, prone to errors

- 📅 Machine servicing forgotten till it breaks down

- 📁 Staff saving files in USBs or personal emails

- 📦 Stock mismatch during audit or re-ordering

- 🔄 Repeat clients, but no past order details handy

- 🤝 QC issues caught too late in dispatch

- 📞 Vendor invoice missing, PO not matched

- 📉 Don’t know actual vs planned production output

- 📦 Finished goods ready, no delivery planning done

- 📋 Staff assigning jobs verbally — gets missed

- 📎 Can’t trace which operator worked on which part

- 💼 Trial samples made, then lost or forgotten

- ⏳ Delay in customer approval or design feedback

- 📊 No clarity on which product line is profitable

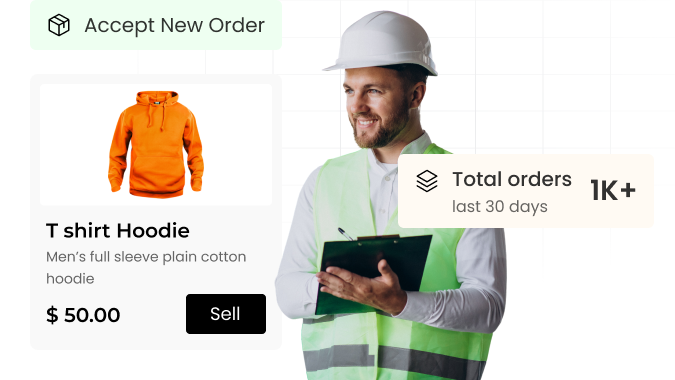

- 📋 Job card system with task, material, quantity, deadline

- 🧾 Entry logged by item, supplier, batch, and date

- 🏭 Live status board of each stage — pending, in-progress, done

- 📎 Attach designs or instructions directly to job card

- 📤 Auto-packing slip generated with every invoice

- 💰 Payment log visible per customer with alerts on overdue

- ✅ One-click GST invoice with linked PO, delivery, and tax info

- 🔧 Service reminder based on running hours or date

- 📂 All files saved client-wise, job-wise, access controlled

- 📊 Live inventory report with inward, outward, damaged stock

- 📖 Complete order history with rate, item specs, and timeline

- 📋 Quality check log updated stage-wise with pass/fail notes

- 📑 Match PO, delivery note, and vendor bill in one screen

- 📈 Report showing shift-wise target vs actual with reasons

- 🚚 Dispatch plan created based on location, client, quantity

- 📲 Assign tasks digitally with time, staff, machine info

- 🧑🏭 Operator log per job — with timings and remarks

- 🎯 Sample records saved with customer feedback and photo

- 📨 Send approval link, track response date and comments

- 💹 Item-wise profit, cost, and margin report per client or job

Earlier, we started the day with a verbal target. But by end of shift, no one had full clarity. Now, each batch or order is tracked — planned, in-progress, or completed — without waiting for verbal updates.

- • Shift-wise production panel

- • Status by machine, product, or order

- • No need to call every supervisor again

We used to over-order or under-order. Now, the system shows current stock, pending orders, and usage trend. We plan material better — no last-minute shortage or dead stock.

- • Real-time inventory by material type

- • Consumption linked to production

- • Alerts when minimum levels are reached

Earlier, one delay in finding a job card slowed the entire process. Now, everything is issued from the CRM — with instructions, drawing references, and team allocation.

- • Digital job card generation

- • Assigned staff and machines logged

- • Status tracking from start to finish

If one batch had an issue, we used to rely on memory. Now, QC data is saved per batch — who checked, what they found, what was done. It protects our name in front of clients.

- • QC status with photos and notes

- • Linked to dispatch and invoice

- • Creates real quality history, not just assumptions

Dispatch used to involve 10 calls a day — is it ready? Is packing done? Is the truck booked? Now, the CRM shows real-time packing and dispatch status, and even PODs after delivery.

- • Order to dispatch tracking

- • Packaging and loading logs saved

- • Delays flagged before they become client issues

When machines stopped, we noted it mentally or on whiteboards. Now, downtime entries are tracked. Reasons are recorded. It helps improve planning, not just react.

- • Downtime category (machine/fuel/labor) logged

- • Duration and technician remarks saved

- • Patterns help us reduce future losses

Many clients repeat the same product after 6–8 months. Earlier, we searched files. Now we open their name — old specs, QC notes, dispatch method — all ready. We restart faster and serve better.

- • Client-wise order history

- • Specs, changes, complaints tracked

- • Builds stronger client relationships

Earlier, supervisors verbally distributed work. Now, shift tasks are visible per team. They know what to start, and updates come back in the same flow — even if there’s a change.

- • Task assignment by team or person

- • Status: Pending / In Process / Done

- • Improves accountability on the floor

Earlier, we only noticed when a machine failed. Now, usage time, output, and error logs are recorded. We start seeing which machines are strong, and which need attention soon.

- • Output per shift saved

- • Downtime reason tagging

- • Helps in preventive maintenance and replacement

Whether on site or not, the factory owner logs in and sees what’s moving — what’s pending, which team is working, what’s ready for dispatch. No calls. No daily check-in pressure.

- • Dashboard view by product, team, order

- • Alerts for delays or urgent decisions

- • Keeps control without being physically present

Earlier, we started the day with a verbal target. But by end of shift, no one had full clarity. Now, each batch or order is tracked — planned, in-progress, or completed — without waiting for verbal updates.

- • Shift-wise production panel

- • Status by machine, product, or order

- • No need to call every supervisor again

We used to over-order or under-order. Now, the system shows current stock, pending orders, and usage trend. We plan material better — no last-minute shortage or dead stock.

- • Real-time inventory by material type

- • Consumption linked to production

- • Alerts when minimum levels are reached

Earlier, one delay in finding a job card slowed the entire process. Now, everything is issued from the CRM — with instructions, drawing references, and team allocation.

- • Digital job card generation

- • Assigned staff and machines logged

- • Status tracking from start to finish

If one batch had an issue, we used to rely on memory. Now, QC data is saved per batch — who checked, what they found, what was done. It protects our name in front of clients.

- • QC status with photos and notes

- • Linked to dispatch and invoice

- • Creates real quality history, not just assumptions

Dispatch used to involve 10 calls a day — is it ready? Is packing done? Is the truck booked? Now, the CRM shows real-time packing and dispatch status, and even PODs after delivery.

- • Order to dispatch tracking

- • Packaging and loading logs saved

- • Delays flagged before they become client issues

When machines stopped, we noted it mentally or on whiteboards. Now, downtime entries are tracked. Reasons are recorded. It helps improve planning, not just react.

- • Downtime category (machine/fuel/labor) logged

- • Duration and technician remarks saved

- • Patterns help us reduce future losses

Many clients repeat the same product after 6–8 months. Earlier, we searched files. Now we open their name — old specs, QC notes, dispatch method — all ready. We restart faster and serve better.

- • Client-wise order history

- • Specs, changes, complaints tracked

- • Builds stronger client relationships

Earlier, supervisors verbally distributed work. Now, shift tasks are visible per team. They know what to start, and updates come back in the same flow — even if there’s a change.

- • Task assignment by team or person

- • Status: Pending / In Process / Done

- • Improves accountability on the floor

Earlier, we only noticed when a machine failed. Now, usage time, output, and error logs are recorded. We start seeing which machines are strong, and which need attention soon.

- • Output per shift saved

- • Downtime reason tagging

- • Helps in preventive maintenance and replacement

Whether on site or not, the factory owner logs in and sees what’s moving — what’s pending, which team is working, what’s ready for dispatch. No calls. No daily check-in pressure.

- • Dashboard view by product, team, order

- • Alerts for delays or urgent decisions

- • Keeps control without being physically present

Curious Minds Ask, We Answer

Yes. You can log every order request, client details, and product requirement — and follow up with clarity at each step. 📋

Definitely. You can create buyer profiles, check deal history, and note requirements like size, quantity, or delivery date. 🧾

Yes. You can assign dispatches, upload tracking info, and mark deliveries complete — your team stays on the same page. 🚚

100%. Even a workshop or job shop can use it to manage quotes, orders, raw material needs, and billing — everything neat and simple. 🏗️

Yes. You can store vendor info, track delivery cycles, and note consumption — it helps in planning and avoiding overstock or shortage. 📦

You can log inspection notes, defects, and approvals per batch or product — so your quality data stays clean and traceable. ✔️

Yes. You can attach PDFs, blueprints, or reference images with each deal or product — ready to share with staff or buyers anytime. 📁

Yes. Sales can handle leads and follow-ups, while operations manage orders and production — all working in sync from one system. 👥

You can see what the client ordered last, what specs they liked, and when they usually reorder — makes retention smoother. 🔁

Yes. You can create, save, and send these documents within the CRM — no switching between tools. 🧾

You can log the issue, assign it to your team, and track updates — your client is informed, and your records stay honest. 🛠️

Definitely. You can manage overseas buyers, shipping docs, and schedules — even store compliance files like CE, RoHS, etc. 🌍

Yes. You’ll get reports on team performance, dispatch timelines, and lead closure rates — helps in future planning. 📊

Yes. You can separate factories, assign team members, and monitor status separately — while you see everything from the top. 🏢

Don’t worry. All tasks, updates, and documents stay recorded. You can assign the project to someone else with zero confusion. 🔄